With the development of modern industry, the requirements of mass production, high precision, high productivity and improved production conditions of die forging parts make the advantages of electric screw forging press widely valued, and its proportion in forging machinery is increasing.So how to buy a foeging press?

The basic reference for selecting forging press is suitable for production, advanced in technology, reasonable in economy, and the reliability and maintainability of equipment are important references for selecting forging press.

Reliability is a prerequisite to maintain and improve equipment productivity.People invest in equipment in the hope that it will work trouble-free in order to achieve the desired purpose, which is the concept of equipment reliability.Reliability depends largely on the design and manufacture of equipment.Therefore, the design and manufacturing quality of equipment must be considered when selecting equipment.When selecting the reliability of equipment, it is required to make the average failure interval of its main parts longer and better. Specific analysis can be carried out from the aspects of safety factor, redundancy design, environment design, component stability design, safety design and man-machine factor.

Good maintainability can reduce maintenance time and cost.The equipment with good maintainability should meet the following conditions: the equipment system design is reasonable, the structure is relatively simple;Reasonable assembly of parts and components, easy to disassemble, easy to assemble, easy to check;Parts, accessories of universal, standard, good interchangeability, easy to choose;Lubricity, good sealing, easy to replace lubricating oil, sealing components easy replacement.

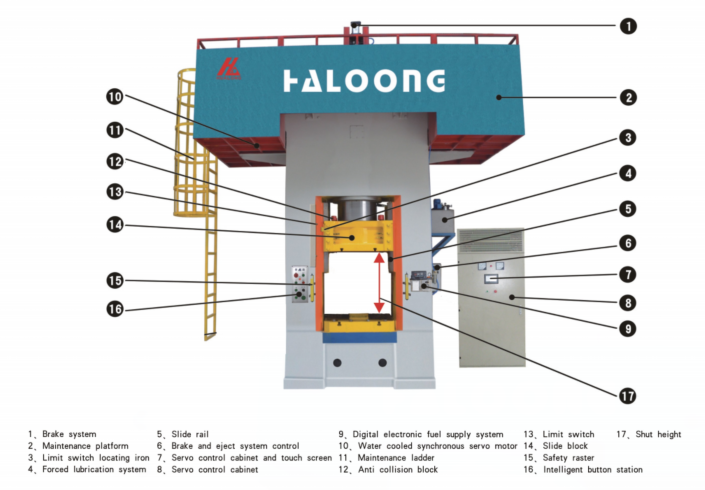

Haloong HLDS electric screw forging press is driven by hydrostatic screw, nut and hydrostatic bearing with a fully sealed structure, which not only effectively insulates the outside dust, but also makes the slide block have better positioning and orientation when moving up and down.The service life of screw and nut is increased 3-5 times.It greatly reduces the maintenance and maintenance cost of the equipment in the later period, and the overall structure is simple and the transmission chain is short.It is a good choice for forging press.