Gear is a wheel-like mechanical part that relies on the transmission of torque of teeth. By combining with other mechanical parts, it can realize functions such as changing speed, changing direction and form of movement.Due to the advantages of high transmission efficiency, accurate transmission and large power range, gear mechanism is widely used in industry, and its design and manufacturing level directly affects the quality of related equipment.

Forging gear is machining gear blank, the blank after repeated hammering, refined the organization, so that the internal structure of the gear more compact, thus improving the bearing capacity of the gear.

The following is a brief introduction to the manufacturing process of high-precision gear.

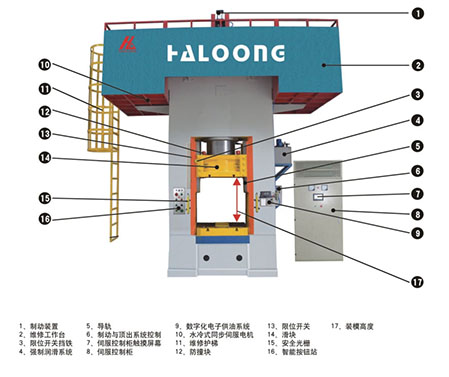

Hot die forging is still widely used auto gears forging process and forging technology in recent years on the axial obtained widespread use, electric screw press is especially suitable for complex forging, which not only forging with high precision, small order process allowance after, and high efficiency, especially in recent years the rapid development of servo technology, has wide application in gear precision forging.

The purpose of this process is to be suitable for post-sequence gear cutting to prepare for final heat treatment, which can effectively reduce heat treatment deformation.

For the choice of gear positioning datum, because the gear structure shape is different, the positioning datum is different.For example, the gear with shaft mainly adopts the positioning of the center, the precision of the center positioning is high and the datum can be unified.

Forging eliminates metal raw materials in the smelting process of as-cast loose defects, such as advanced forging equipment such as electric screw press forging precision controlled, not only optimize the microstructure, at the same time due to the metal streamline the intact, more lasting, on the mechanical properties of the forgings forging can also save material consumption, greatly improve the utilization rate of material, mechanical forging will develop in the future.