Lean production is what experts at the International Automotive Program at the Massachusetts Institute of Technology call Toyota's just-in-time production (JIT) approach in Japan.Refinement, that is, less and more refinement, without the input of superfluous factors of production, but with the production of the necessary amount of marketable products at the appropriate time, benefit -- that is, all business activities should be beneficial, efficient, and economically efficient.Its purpose is to be driven by customer demand, so that enterprises with the minimum investment to obtain the best operating efficiency and improve the response speed to the market.

The benefits of forging factory output are reflected in the form of "forging price".For example, for the forging factory of automobile production plant, this price is reflected by the "whole vehicle price", while lean production is mainly reflected in eliminating various waste phenomena, and the main evaluation indicators are reflected in cost control, quality, efficiency and other aspects.

(1) Material cost.Material cost is the majority of forging cost, which is mainly reflected in cost in the form of "material consumption quota" and "material unit price".

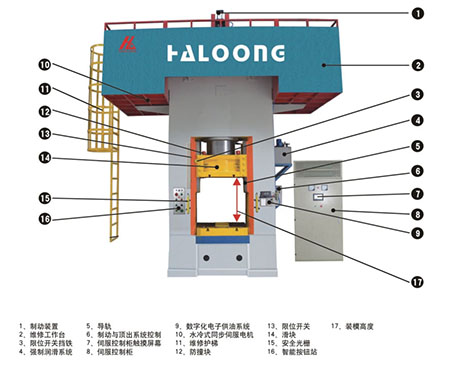

(2) Labor cost.Reflect the labor cost waste caused by direct production personnel.To control labor cost fundamentally, we need to keep improving production equipment to ensure the production of lean forgings.Such as electric screw press, advanced precision in forging can greatly save labor costs.

(1) Waste.In the form of "scrap rate", including production waste, commissioning waste and process waste, including repair cost, repair tool consumption, repair site occupation and production efficiency reduction.

Productivity.Reflected in the form of "effective stamping", the equipment itself by the highest continuous stamping capacity, equipment mobility, equipment precision rate and other factors.Servo drive in the electric screw press is the embodiment of choice controllable, stamping efficiency is high, the response speed is fast, in improving the production efficiency has great progress.

With its core concept of reducing waste and responding quickly to meet customer needs, lean production has been paid more and more attention by many forging factories and applied to different degrees.However, different plant conditions and cultural background, the degree of lean production is also very different.Domestic more emphasis on quality, stable production, lean production created the value of more embodied in the form of "premium" products, in terms of production equipment purchasing advanced technology of servo drive electric screw press is most obvious, and the autonomous system in the aspect of lean production is trying to study department of Japanese enterprise, there has been a very big room to improve.