Intelligent forging is emerging in the area of staff and technical tools for information change, through the comprehensive utilization of intelligent decision-making, intelligent industrial process and intelligent resources, improve the production performance and process, etc., and then create and provide the sustainable high value products, thus, intelligent forging is the inevitable developing trend of manufacturing production process automation.

Forging is a basic and constructive industry in China, which occupies a major position in China's manufacturing industry. Many key parts and components in automobile, aviation, Marine engineering and other major fields are processed and formed through forging links.The development of automation in the forging industry tends to be mature. However, automation only meets the requirements of production quantity and tempo. In today's increasingly mature automation, it cannot become the core competitiveness of enterprises, especially compared with intelligent factories, the following disadvantages tend to occur.

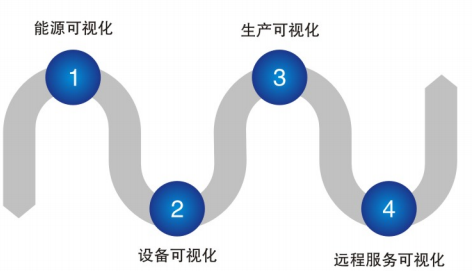

1. Unable to build the information system environment.The traditional forging equipment can only meet the control of the production action, and cannot record the information of every production process, and cannot introduce the information system and the transparency of production process information in the production process.

2. Whether the forgings produced are closely connected with the following processes, and whether they can be accurately released and replaced quickly when product varieties are switched.The utilization rate of equipment cannot be improved, the idle time cannot be reduced, and without a good production scheduling plan, the equipment cannot exert its maximum production capacity.

3. At present, the equipment of forging enterprises can only realize the switch of a single or a few varieties, which cannot meet the increasingly diversified market demands. Switching products even requires switching equipment, which wastes a lot of manpower and time.Therefore, only through the development of the entire enterprise information, intelligent technology, forging enterprises can make the industry leading position.

1. The first thing you need to build the forging industry workshop data model, change the traditional mode of production, application of new production equipment, to achieve from the workshop production to the final finished product, inspection, etc. The whole process of real-time data acquisition, with comprehensive analysis of various data in description, establish dynamic model with time property and mapping data.

2. Set up intelligent production line, timely carry out the follow-up process and transfer of forgings, reduce the idle time of equipment, improve the utilization rate to the highest level, and give full play to the productivity.

3. As for forging equipment, the development of forging equipment is carried out synchronously with the development of industrial technology. From its long and long history, it can be seen that the development trend of forging equipment is from the original simple development to high efficiency and numerical control.Especially now the international market are mostly using the servo electric screw press, the domestic market also gradually started to use more intelligent charging servo technology, the more advantage in market competition, especially the development of domestic servo technology, zhengzhou hualong iot and intelligent production management is a research and development of intelligent management system for forging industry, through the intelligent perception, human-computer interaction, large data collection and analysis, combined with equipment automation, to realize intelligent manufacturing process and manufacturing equipment.

The forging development is evaluated from all aspects, and the problems are further optimized through the analysis of the comprehensive evaluation results, so as to improve the workshop's production capacity, production efficiency and the enterprise's ability to quickly respond to the market.