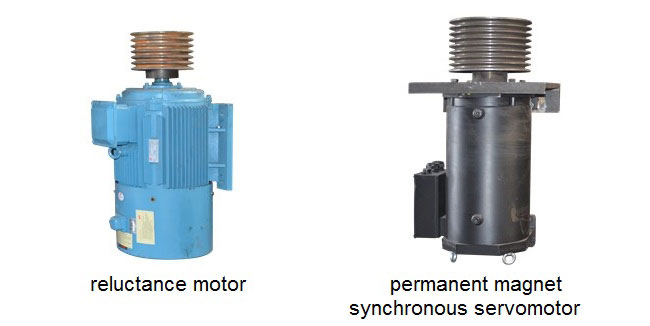

The first generation of HALOONG electric screw forging press used switched reluctance motor, the second generation started to use servo motor, until now the fourth generation of products. In the process of product upgrading for several generations, we analyzed the difference between switched reluctance motor and servo motor based on the effect of customers:

Switched reluctance motor is called never break motor, because of the switched reluctance motor burn out under the condition of a group or several groups of coil, still can work, only the power of the motor reduced, the speed is slower, not all of a sudden stop. But the advantage is that cannot under the precise control, for example, mining machinery, coal machinery, such as the running equipment if the motor is broken, just strength reduced, slow, not break down. But this advantage for precision control of electromechanical equipment, is equal to both advantages and disadvantages. Applied to refractory material, for example, the electric screw press molding equipment, since the size of the electric screw press is on pressure make formed tile body, weight, and achieve a standard, crushing strength, but because the motor is burnt out a set or group of coils, strength reduced, slower, due to the size of the product density change. This is invisible problem to be found by the workers. It is only found during measurement. Generally, enterprises will not doubt whether the motor is burnt until they find no reason to eliminate all obstacles, but this is a hidden defect, which is hard to find.

The size of a switched reluctance motor is twice of the servo motor, big size, heat dissipation is not ideal, noisy, had rushed phenomenon (inertia when stop, cannot sudden brakes), starting current is big, big impact on the grid, and belongs to the analog signal control, the accuracy is not enough, need to add a frequency converter have a strong implementation of the so-called free program control, so use of switched reluctance motor screw press is called electric SPC press.

Digital servo motor is in the true sense control motor, the motor can arbitrary controls motor speed, angular velocity, torque, power and pulse control by digital programming (rotor a circle of 360 degrees 10000 pulse signal can be set), has been widely used in the global high-end equipment, for example, a variety of electric vehicle, aviation, satellite navigation, rockets, military equipment, such as the space station. This is also the reason why the first generation of HALOON machinery electric screw press is replaced and upgraded.

Switching reluctance electric screw press is only a prototype of servo CNC electric screw press. For forging, if control precision is not high, the switch reluctance motor screw press should be ok, if it is for dust molding, precision metal forming, the use of precision forging, switched reluctance electric screw press will not be perfect. At present, the domestic forging press association is vigorously promoting and popularizing the application of servo CNC forging press, aiming to improve the equipment level and product level of the whole industry.