Friction press, as the name suggests, is a friction driven spiral press, also known as the double-disc friction press, which USES the flywheel and friction disc contact transmission, with the relative motion principle of screw and nut and work.

However, the friction press can not meet the needs of industrial production in the new era due to its high energy loss, easy damage of parts, low working efficiency and high labor intensity.At present, after many years of research and development on the manufacturing technology of the press at home and abroad, most of them adopt advanced permanent magnet synchronous servo motor, but there are still some enterprises using friction press. Therefore, it is also necessary to transform the friction press. Zhengzhou Hualong Machinery Manufacturing co., Ltd. will provide you with the transformation of friction press.

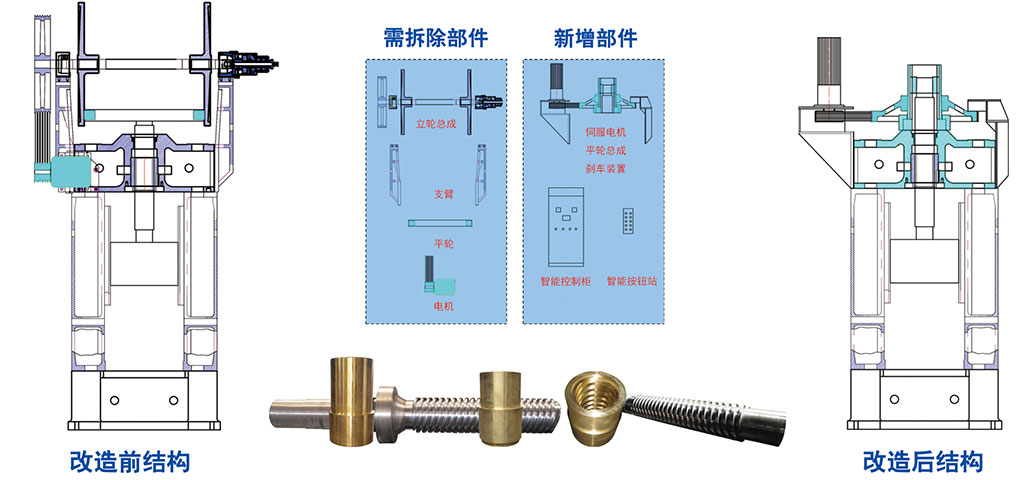

Remove the horizontal axis and arm of the friction press, and turn the original plane into a large pulley with spline. The large pulley is driven by the servo motor to make the screw rotate.

Remove the original motor and electrical, replace with superior performance of the servo motor and control system.Reduce strike time and provide efficiency.

Increase the performance of reliable, long-term stability of the pneumatic automatic lubrication device, the bearing, spline sleeve for automatic lubrication.

Use four brake

Double cylinder brake is installed on the upper selling surface of flywheel

Add four springs to ensure effective braking in the state of power loss and air loss

Servo motor zero speed and constant torque braking

The use of safety grating ensures rapid braking in any state

Modification of demoulding system

The demoulding cylinder is controlled by PLC to realize manual and automatic demoulding.

According to these aspects of the friction press, not only the high degree of automation, good quality stability, but also safe and energy saving, because of the short transmission chain, less vulnerable parts, maintenance costs also reduced a lot, to a large extent can help small and medium-sized enterprises to solve this problem.