With the rich product categories and the rapid replacement of the old and new industries lead to the fierce market competition.The traditional rigid production line for processing a single variety is no longer suitable for the needs of the current market development. The highly flexible and efficient servo cnc press forging equipment can improve product quality, product consistency, product precision and other aspects to improve product quality and enhance the market competitiveness of enterprises.

This requires that the press required by the production of products not only has high production efficiency, high product precision, but also can bear large load, and has greater flexibility, can quickly change the output trajectory.However, the traditional mechanical press cannot meet the above requirements due to its single motion characteristics and poor process applicability. Therefore, a new generation of flexible press is urgently needed to replace the traditional mechanical press.The production of servo controlled press has greatly improved the forging products.

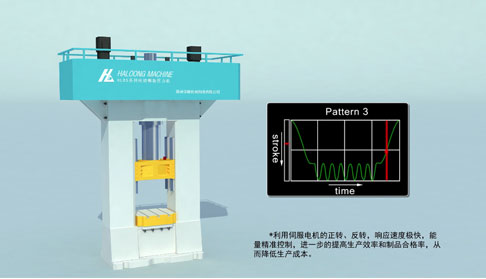

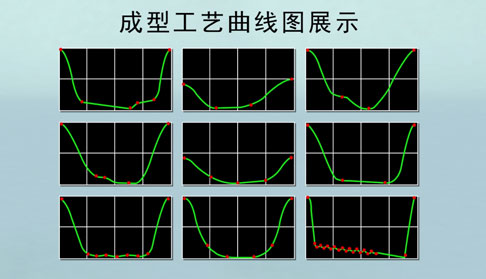

The control of slider movement has been digitized.The slider motion curve can be set according to the different production process and mold requirements. The slider "free motion" can be realized through programming, which greatly improves the intelligent degree and application range of the press, and can realize high difficulty and high precision machining.

The stroke of the slider can be adjusted according to the production process, and the number of stroke of the slider can be numerically set in a large range according to the working condition and the need of automatic wiring, so as to improve the productivity.Compared with the traditional mechanical press, the servo-driven press can improve the production efficiency by more than 20%.

The full closed loop control system composed of linear sensors can realize high precision position control.Accurate numerical control of working energy and speed makes the workpiece precision and die life greatly improved.

Servo motor driven press high automation and intelligent level, improve the working characteristic of the press, is the development direction of a new generation of forming equipment, in the developed countries of the products has been widely put into practical application, and in domestic at present only some forward-looking companies have begun to use, because they are more understand the right equipment, in order to more efficient production, to help enterprises in an impregnable position.