Die forging of screw forging press is widely used in medium and small batch production workshops and some special production lines.According to the different driving mode, the screw forging press mainly has friction press, switched reluctance press, and servo CNC screw forging press.

Advantages of screw forging press

1. The process is widely used.The screw forging press can provide more energy for the process with larger deformation, and more force for the process with smaller deformation, so the screw forging press can complete various processes of die forging, extrusion, fine pressing, correction and bending.The screw forging press has a forgings device, which can carry out some processes such as long forgings, extrusion cylinder, closed forgings and precision forgings that are difficult to be completed on the forging hammer.In addition, as the strike speed of the screw forging press is lower than that of the die hammer, the recrystallization process is more fully carried out in the metal deformation process, which is conducive to forging some non-ferrous metals and low-plastic alloy steel forgings with lower recrystallization speed.

2.

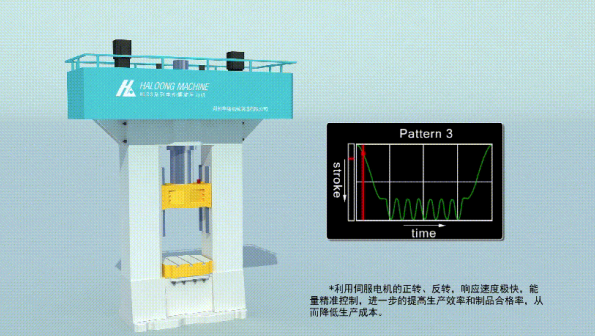

The life of forging die is longer and the cost is lower. The striking speed of the screw forging press is much lower than that of the die forging hammer, the die bears less impact force, and the screw forging press is beneficial to the insert die, so the corresponding module size can be reduced. In addition, during die forging on the screw forging press, the contact time between the blank and the die is short, the heat from the blank to the die is less, and the die has a long life. Especially servo CNC screw forging press, speed can be set freely, at the bottom dead point, the slider speed is very fast, contact time with the mold is very short, mold temperature change is not big, therefore, can greatly extend the life of the grinding tool.

3.High vertical accuracy of forgings.In the hot die forging press die forging, the same batch of blank, such as size or heating temperature changes, the body and other parts will have different elastic deformation.The difference of the deformation will be reflected in the height and size of the forging, thus affecting the vertical accuracy of the forging.In the die forging of the screw forging press, because there is no fixed bottom dead point, the elastic deformation and thermal deformation of the body and other parts can be compensated by the slide displacement, that is, the vertical precision of the forging is guaranteed by the mold, so the vertical precision of the forging is high.

4.The forging press equipment has low manufacturing cost and convenient to use and maintenance.

5.Screw only rotating motion of screw forging press, slider ratio of height to width of friction press increased significantly, so the ability to resist bias load greatly improved, can be used for multi-mold chamber forging.

With the continuous development of science and technology, servo CNC screw forging press by virtue of the advantages of digital control, is favored by more enterprises.

High precision, high flexibility, so that it can complete more high precision, high value-added products, for the enterprise to create more revenue.