Titanium and titanium alloy is a new metal structure material developed after the second world war. Its main characteristic is that the density is only half of steel and nickel base alloy, so the specific strength is high; At the same time, it has good heat and corrosion resistance.

Therefore, it is firstly applied in aviation, chemical industry and shipbuilding industry.Carbon, alloying elements and gaseous impurities, especially oxygen, in titanium alloy (especially as-cast titanium alloy) have great influence on the plasticity of titanium alloy.

In the process of forging with forging hammer or f

orging press, the deformation speed of titanium alloy cannot be too great.According to the upsetting experiment of TA3 titanium alloy, the allowable upsetting deformation on forging hammer is not more than 45%, while the allowable upsetting deformation on forging press is up to 60%.Therefore, titanium alloy forging in the forging press is more suitable.

The core of thermal deformation of titanium alloy is a good combination of deformation temperature and deformation degree.The reasonable deformation degree is one of the important conditions to ensure certain performance requirements of titanium alloy forgings.

Titanium alloy can be free forging and die forging on forging hammer and forging press.The comparison between the quality of the compressor disc forged by two kinds of forging equipment and other kinds of forgings shows that the microstructure and mechanical properties of the

two are similar.Titanium alloy forging hope to use a smaller speed of the press.The main reason is that the forging on the forging hammer deformation thermal effect is large, the risk of metal overheating is large, and may cause the structure of the thick and plastic decline.

The forging process characteristics of titanium alloy are as follows:

1. High deformation resistance: the deformation resistance of titanium alloy is higher than that of steel at the forging temperature. The deformation speed has a great influence on the deformation resistance of titanium alloy. The unit pressure during deformation on the forging hammer is several times higher than the unit pressure during deformation on the

forging press. Therefore, from the point of view of reducing the energy consumption of die forging, it is better on the forging press than on the forging hammer.

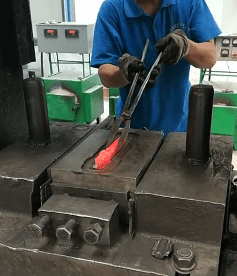

2, Poor thermal conductivity: the thermal conductivity of titanium alloy is worse than that of steel, aluminum and other metals. The thermal conductivity of titanium alloy is 1/5 of iron and 1/12.5 of aluminum. Therefore, the surface cooling of the forging billet is fast. In order to reduce the cooling speed of the blank surface, it is very important to preheat the forging die, clamp and other tools that are in direct contact with the blank.

3,High viscosity and poor fluidity: compared with steel, titanium alloy has high viscosity and poor fluidity. Die forging (including extrusion) must be enhanced lubrication, otherwise easy to produce mucous membrane phenomenon, and die forging extrusion pressure will be due to the sharp

increase in friction and significantly increased. In addition, the forging may be torn during the return journey of the module or hammer head.

Air cooling is usually used after forging titanium alloy forgings. However, depending on the type of titanium alloy and the strength and plasticity required for the parts, heat treatment is sometimes performed after forging.