Forging press as long as it is through the screw structure to make the slider up and down forming torque press, are regarded as a forging screw press. Screw press and forging hammer, mechanical press and other forging machinery, universal sex is strong, can be used for forging, blanking, deep drawing process, has been widely applied to the production of die forging process, according to the classification of the driving mode of screw press, friction forging screw press and the characteristics of the servo electric forging screw press die forging and what is the difference?

1) By the impact force to deform the metal, but the speed of the slider is low (0.7~1m/s), the number of strikes per minute is less, suitable for forging low plastic alloy steel and non-ferrous metals.

2) non-rigid connection between screw and slider, poor ability to bear eccentric load, generally can only be single die forging.

3) there is a ejection device, you can forge a small die forging slope (or no die forging slope) forgings, high precision forgings.

4) The stroke is not fixed, it can realize light strike and heavy strike, can carry out multiple forging strike, but also can carry out bending, fine pressure, correction and other processes.

1) High precision forgings, precision forging, such as blades, etc.

2) The guide rail gap is small, the guide length is long, the guide precision is high, the anti-partial load ability is strong, can be double station or even multi-station forging.

3) Energy pre-selection can be carried out, and digital precision control of energy and striking force can make the mold bear the best stress and the appropriate die time, and the service life of the mold is high.

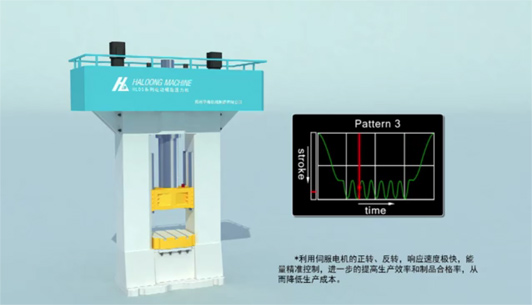

4) Higher transmission efficiency and stroke times, faster forming speed.

Servo electric forging friction screw press and forging new screw press in the use of die forging on contrast: forging servo screw press with low energy consumption, energy saving 55%, high control precision, the partial load resistance is good, it can realize multistep forging and other advantages, is the upgrading of the friction screw press forging products and alternative products.