After the forging press factory has selected the right forging press equipment, there are often a lot of questions about the installation of the die.In fact, there are different installation methods for different forging and pressing equipment.

The correct installation of the die is not only one of the guarantee conditions for obtaining qualified forgings, but also very important for die life, equipment accuracy, production safety, flow efficiency, etc.

Press die forging, forging die is generally installed in the die base, die base with a guide to ensure the precision of the forging die. When installing die base, the consistency and coordination between the slider guide and die base guide should be guaranteed to prevent the deviation and wear of the guide part.

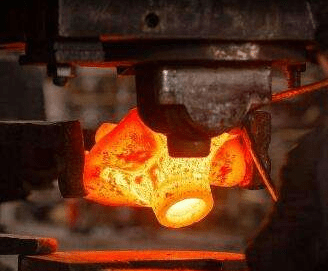

forging on the die

In the process of production, it is necessary to check whether the guide part of the mold base fits normally and make timely adjustment. When the upper die is forged, the swallowtail part of the upper die and the lower die is fastened on the hammer head and the lower die base by the wedge iron. In the process of clamping wedge iron, the upper die should be driven by the hammer head to tap the lower die, so that the forging die is easy to tighten.

The hammer is moulded for installation. Easy to adjust, generally have a lock. The key blocks must be carefully adjusted when the die is installed to ensure consistency and coordination between the hammerhead guide and the die guide.

Due to the inconsistency of forging die length, each set of forging die swallowtail is inconsistent with the fitting surface of the hammer head and swallowtail groove of the lower die base (including upper and lower contact surfaces and sides). If the forging die of short size is used for a long time, the surface where the hammer head, the lower die base and the swallowtail of the forging die fit together will be deformed and dented.s a result, in the installation of a long forging die, there is a gap in the bonding surface, the press should be timely to repair the hammer head and the lower die base. And should choose the alloy steel with better material to manufacture the hammer head and the lower die base, and through heat treatment or surface hardening, the hardness than the forging die installation part of the hardness is higher.

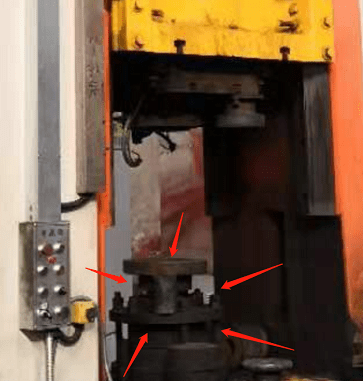

die on the forging press

Generally speaking, the forging press die forging mold stability is better than the hammer, but do enough work, plus the usual maintenance inspection, the correct installation of the mold is not difficult.